Expert Team

Specialized team to produce quality products

Quality Supervision

Our production unit is time-to-time checked and guided by the research professionals

24/7 Support

We provide best solutions to your problems

Welcome to Jinton

20 Years Experience

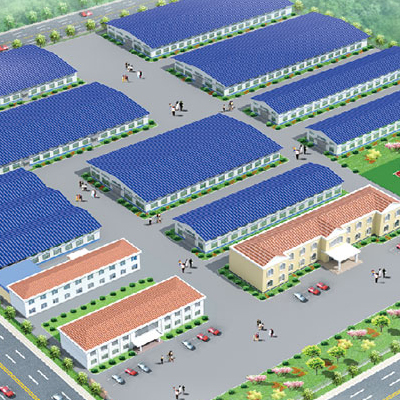

Jinton is located in Hainchu Taiwan and in China,it covers an area of 50,000 square meters. Own 250 staff, among which 36 are R&D members. Its main products are grooved pipe fittings, powder coated steel pipes and valves, which are widely used in many fields such as fire fighting, electric power, telecom,municipal construction, chemical, mine etc.

Jinton obtained FM approvals,UL certificate and ISO 9001 certificate. It imports advanced production line such as DISA line, pipe fitting production line, powder coated pipe production line, electrostatic coating production line. Production ability is 100,000 ton for grooved pipe fittings and 100,000 ton for coated pipes per year. The company cooperates with Wuhan University, Shandong University and many other design institutes to develop ultra high molecular wearing pipe, wearing ceramic pipe and fittings. It has its own R&D system and lab, equipped with advanced inspection and detection equipment. It is awarded Shandong high & new technology enterprise in 2011. Jinton products are very popular in Taiwan and China market, exported to Japan, Canada, UK, India, The United Arab Emirates and other countries. Jinton company is ready to do business with new and old costumers all around the world. Learn More